Space and Astronomy

Brochures

pdf - 7.32 MB

pdf - 114.23 KB

pdf - 163.98 KB

pdf - 201.86 KB

-

Silicon carbide SiC (advanced ceramics) for ground & space telescopes and scientific instrumentation

Boostec® SiC provides an ideal solution for instruments requiring exceptional thermomechanical stability.

Using Boostec® technology, whole instruments can be made in SiC: structure and detector supports as well as the mirrors themselves.

The optical face of the mirrors can receive a SiC CVD coating to produce a completely non-porous surface, for a flawless polishable finish.

-

Space optical instrumentation: 20 years of unique know-how

Mersen Boostec designs and manufactures:

- monolithic parts up to:

- 1.30 m in diameter for circular parts

- 1.65 x 1.30 x 0.60 m for rectangular parts

- SiC brazed assemblies up to:

- 3.5 m in diameter.

Mersen Boostec's know-how also extends to structural bonding and bolting techniques for assembling SiC parts together or with parts made of other materials.Mersen Boostec is involved in several public and private programs in space optics, ground telescopes and large instruments:

- ELT: Combining high specific stiffness and high thermal stability, the Boostec® SiC material has been selected for manufacturing two very large and challenging parts of the ESO Extremely Large Telescope (ELT). These are the highly stable Reference Body of its M4 adaptive optic and also its fast tip/ tilt M5 mirror

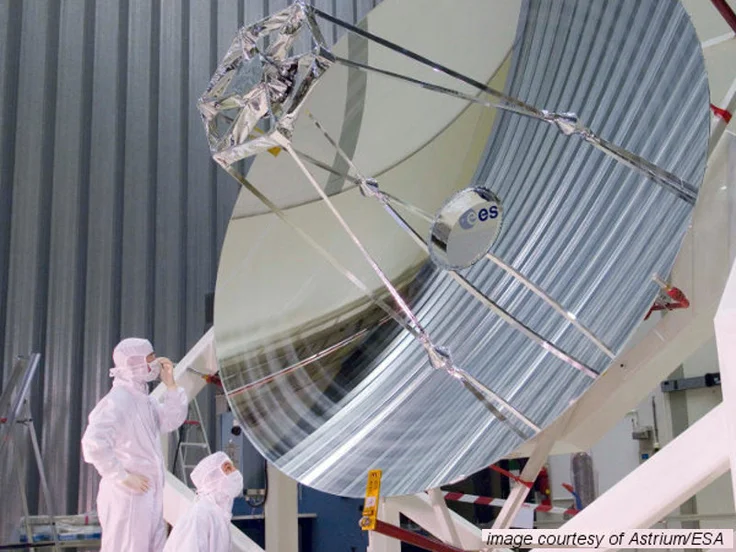

- Herschel: space telescope launched in 2009 with a primary mirror measuring 3.5 m in diameter (the largest in space), made up of 12 sintered silicon carbide segments assembled by brazing.

- Gaia: ESA global astrometry mission (European Space Agency), launched in December 2013.

- Sentinel-2: ESA optical imagery mission: 4 satellites equipped with high resolution multispectral instrument

- monolithic parts up to:

-

-

Product Literature

Technical documentation

Boostec® SiC Silicon Carbide Material

pdf - 7.32 MB | Nov. 28, 2024

A new Technological Step for SiC Mirrors Preparing OTOS

pdf - 838.61 KB | Nov. 28, 2024

CTE homogeneity, istropy and reproducibility in large parts made of Sintered SiC

pdf - 669.61 KB | Nov. 28, 2024

The SiC structure of the EUCLID NISP instrument

pdf - 783.55 KB | Nov. 28, 2024

Full-SiC EUCLID’s very large telescope

pdf - 919.93 KB | Nov. 28, 2024

The SiC Primary Mirror of the EUCLID Telescope

pdf - 423.61 KB | Nov. 28, 2024

The SiC hardware of the Sentinel-2 Multispectral Instrument

pdf - 997.34 KB | Nov. 28, 2024

Press release

Mersen: taking part in the Extremely Large Telescope project

pdf - 238.54 KB | Nov. 28, 2024