Isostatic graphite solutions for continuous casting

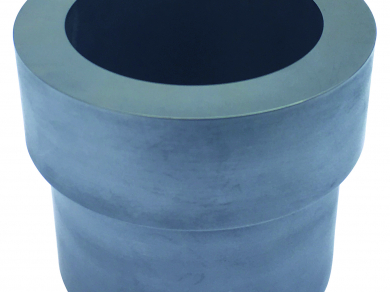

Isostatic graphite dies and crucibles for continuous casting of copper alloy, precious metals and cast iron

Isostatic graphite produced by Mersen is well adapted for continuous casting dies and crucibles due to its unique physical characteristics:

- Capable of withstanding molten metal températures: graphite sublimates at 3,650°C at atmospheric pressure.

- High thermal conductivity: the heat extraction is key to transform the metal from a liquid to a solid state.

- Low coefficient of thermal expansion (CTE) for dimensional stability

Graphite components are critical to the process and allow the metal processing to be monitored continuously from the liquid state to the solid state, while forming semi-finished products (wires, bars, tubes, strips, etc.).

Solutions for:

- Grey and ductile iron

- Brass (Cu-Zn)

- Bronze

- Phosphorus bronze

- Maillechort (Cu-Zn-Ni) - Nickel silver

- Nickel-copper

- Red copper, Phosphorus deoxidized copper

- Aluminium

- Silver, Gold

- Precious metal alloys

Graphite grades for the metal industry

Decades of development in conjunction with metallurgy professionals have enabled Mersen to develop graphite grades that are perfectly adapted to the stresses of these applications:

- The molten metal does not wet our very non-porous and non-reactive graphite..

- It can be easily machined to a polished surface.

Our experts can offer assistance in selecting the grade that best suits the metal in question. Our expertise in precision machining and design is at your service to assist you in creating the most efficient designs.

Mersen's refractory products are used in many other traditional metallurgical applications such as the production of aluminium, casting, and high-temperature surface treatment, among others.

Contact France

Sales & Engineering

F-92231 GENNEVILLIERS France

+33 (0)1 41 85 43 00

Sales & Engineering

215334 KUNSHAN

China

+86 400 162 8288

Sales & Engineering

PA 15857-1488 St Marys

USA

+1 814 781 1234

Sales & Engineering

Contact France

Sales & Engineering

F-92231 GENNEVILLIERS France

+33 (0)1 41 85 43 00

Sales & Engineering

215334 KUNSHAN

China

+86 400 162 8288

Sales & Engineering

PA 15857-1488 St Marys

USA

+1 814 781 1234

Sales & Engineering