Polybloc®, impervious graphite block heat exchanger

Poybloc® graphite block heat exchangers are adapted to the heating, cooling, evaporation, condensation and absorption of highly corrosive liquid chemicals.

This design is one of the most versatile type of impervious graphite heat exchangers.

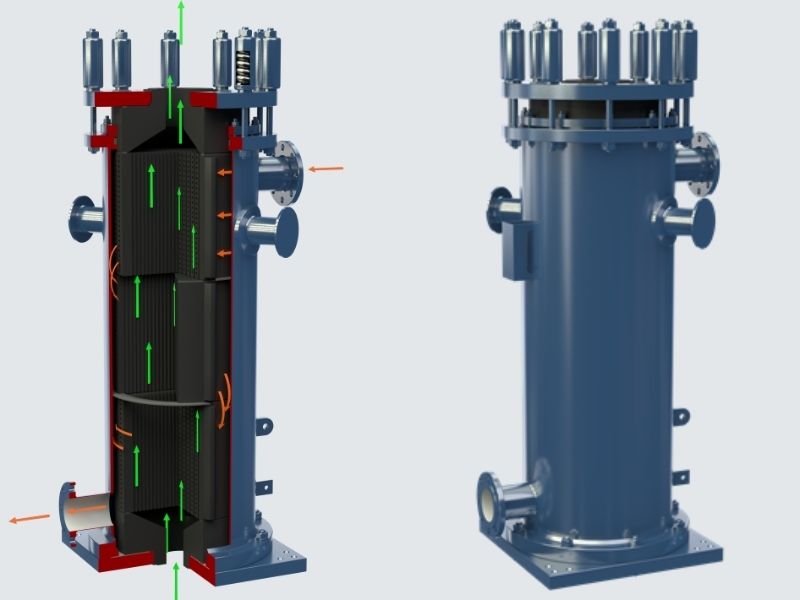

Rows of holes are drilled through graphite blocks both horizontally and vertically to form the process and service channels. Heat is transferred by conduction through the impervious graphite left between the rows of holes which separate the mediums being used. Graphite block heat exchangers consist in a stack of blocks encapsulated in a steel shell.

Polybloc® features

- Graphilor® isostatic or extruded graphite grades

- Heat transfer area up to 1000 m2

- Various block diameters: from Ø100 to 1500 mm

- Design pressure

- Full vacuum to 7 barg on both process and service sides as standard

- Up to 16 barg on service and up to 12 barg on process side on request

- Design temperature: from 200°C (BS), maximum 430°C (XC)

- Various drilling diameters and patterns

- Number of passes on process and service sides can be adjusted to achieve optimum velocities

- Number of blocks can be adjusted to achieve the necessary heat transfer area

OPTIONS

- Gas / Liquid Separation Chamber

- Header with Liquid Distribution for Falling Film Absorber

- Protection against erosion

- Dismountable Headers for easy

Polybloc® advantages

- Versatile, modular, and simple design

- Easy maintenance

- Wide choice of graphite and impregnation types

- Individual blocks can be replaced (no catastrophic failure

Polybloc® applications

- Heating, Cooling, Condensation, Evaporation (falling film or forced circulation), Absorption

- Heavy Chemistry: Phosphoric Acid, Titanium Dioxide, Hydrometallurgy, Vinyl Chloride Monomer, Epichlorohydrin, Plastics, Viscose, Aramid fiber, and many more…

- Fine Chemistry, Specialty Chemistry, Pharmacy: Active Pharmaceutical Ingredient, Crop Protection, Fumed Silica, Silicones, Flavors and Fragrances, Vitamins, and many more…

- Carbon and Stainless-Steel Pickling

Polybloc® TSR (patent pending)

Mersen's new Polybloc® TSR (Thermal stress resistant), offers a greatly improved resistance to thermal shocks.

Block cracking due to thermal shock during condensation

Notwithstanding the superior properties of Graphilor® , significant thermal shocks can trigger mechanical stresses such that the blocks can crack. Let's take the example of a graphite condenser located above a fine chemical process reactor: the hot vapors condense in the holes on the process side, while the cooling fluid, usually chilled water, circulates in the shell on the service side. If the user feeds the process side with vapors at a temperature between 80°C and 100°C, and suddenly feeds the service side with chilled water at 5°C, the graphite is likely to suffer a thermal shock, which could lead to the cracking of one or more blocks in the condenser. The higher the difference between the temperature of the service side fluid and the inlet temperature on the process side, the greater the thermal shock and the greater the risk of block damage.

Mersen Polyblocs® TSR heat exchangers

Mersen has developed a new block design, called Polybloc® TSR (patent pending), offering a greatly improved resistance to thermal shocks. This design reduces the mechanical stresses induced by thermal shock by a factor exceeding 3 and thus considerably reduces the risk of breakage. All new Polybloc® TSR remain fully compatible and interchangeable with all Polybloc® exchanger blocks marketed by Mersen. They are offered in Graphilor® BS, XBS, XTH or XC and for each drilling diameter and pattern currently available.

Contact France

Graphite, PTFE and Process equipment for France, Europe, Middle East and South East Asia

54530 - Pagny-sur-Moselle

+33 (0)3 83 81 60 81

Graphite, Process equipment and Service for USA

24153 SALEM

USA

+1 540 389-7535

Reactive metals and graphite process equipment

201411 Shanghai

+86 21 57 52 77 77

Annular Groove, SiC heat exchangers specialist

D-79689 Maulburg

+49 (7622) 6751 0

Graphite Cubic and Polybloc heat exchangers

Durham Lane Industrial Park

Eaglescliffe TS16 0RH

GREAT BRITAIN

0044(0)1642790100

Contact France

Graphite, PTFE and Process equipment for France, Europe, Middle East and South East Asia

54530 - Pagny-sur-Moselle

+33 (0)3 83 81 60 81

Graphite, Process equipment and Service for USA

24153 SALEM

USA

+1 540 389-7535

Reactive metals and graphite process equipment

201411 Shanghai

+86 21 57 52 77 77

Annular Groove, SiC heat exchangers specialist

D-79689 Maulburg

+49 (7622) 6751 0

Graphite Cubic and Polybloc heat exchangers

Durham Lane Industrial Park

Eaglescliffe TS16 0RH

GREAT BRITAIN

0044(0)1642790100