Mersen Polybloc® TSR

Thermal Stress resistant

Now you can prevent risk of block damage due to thermal stress!

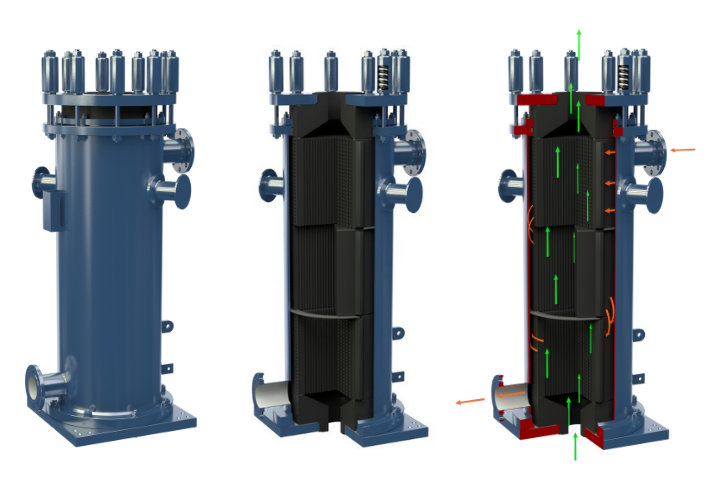

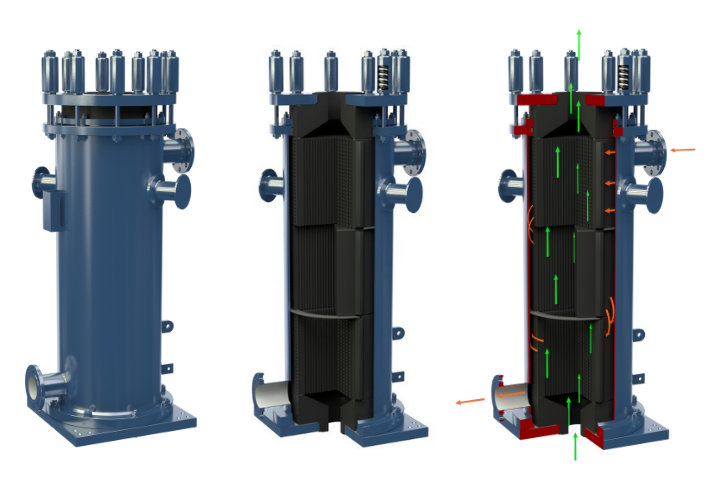

Mersen has developed a new block design: Polybloc® TSR (patent pending).

Mersen's new Polybloc® TSR (patent pending) offering improved thermal stress resistance

Mersen has developed a new block design, called Polybloc® TSR (patent pending), offering a greatly improved resistance to thermal shocks.

This design reduces the mechanical stresses induced by thermal shock by a factor exceeding 3 and thus considerably reduces the risk of breakage.

All new Polybloc® TSR remain fully compatible and interchangeable with all Polybloc® exchanger blocks marketed by Mersen. They are offered in Graphilor® BS, XBS, XTH or XC and for each drilling diameter and pattern currently available.

Polybloc® heat exchangers and Graphilor® graphite

Mersen's Polybloc® heat exchangers comprise of cylindrical blocks of Graphilor® BS, XBS, XTH, or XC, manufactured from either an extruded or an isostatic graphite, impregnated with either phenolic resin, PTFE, or carbon.

Graphilor® is well known for its outstanding corrosion resistance, high thermal conductivity and superior mechanical properties. Polybloc® heat exchangers offer sturdy and modular solutions for ultra-corrosive applications.

Block cracking due to thermal shock during condensation

Notwithstanding the superior properties of Graphilor® , significant thermal shocks can trigger mechanical stresses such that the blocks can crack.

Let's take the example of a graphite condenser located above a fine chemical process reactor: the hot vapors condense in the holes on the process side, while the cooling fluid, usually chilled water, circulates in the shell on the service side.

If the user feeds the process side with vapors at a temperature between 80°C and 100°C, and suddenly feeds the service side with chilled water at 5°C, the graphite is likely to suffer a thermal shock, which could lead to the cracking of one or more blocks in the condenser.

The higher the difference between the temperature of the service side fluid and the inlet temperature on the process side, the greater the thermal shock and the greater the risk of block damage.

Let's talk about your process!

Polybloc®, Graphite Blocks Heat Exchangers

Contact

ACE-France Pagny-sur-Moselle

Graphite, PTFE and Process equipment for France, Europe, Middle East and South East Asia

Downloads

POLYBLOC® TSR Heat Exchanger - Thermal Stress Resistant

Download205.2 KB

POLYBLOC® TSR Heat Exchanger - Thermal Stress Resistant