Electrical discharge machining - EDM

-

Isostatic graphite EDM - Electrical Discharge Machining

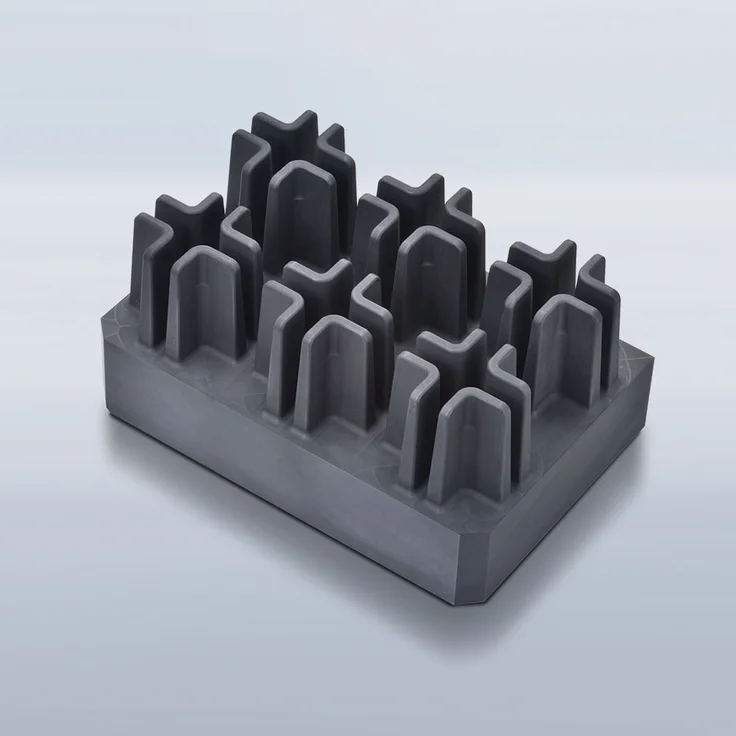

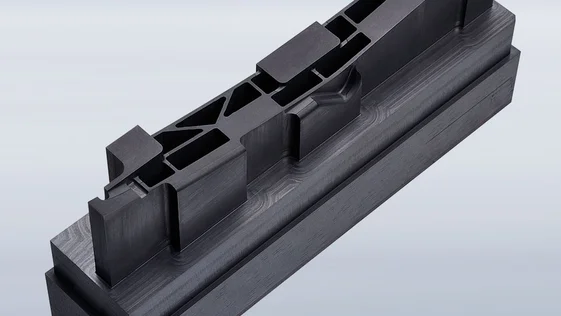

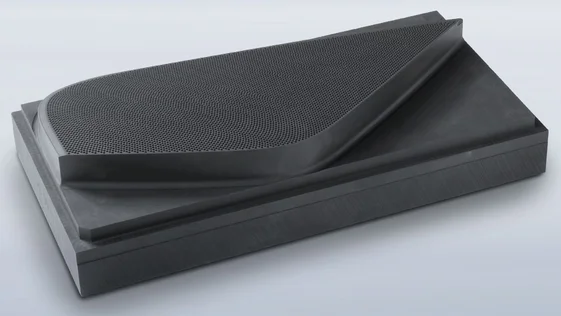

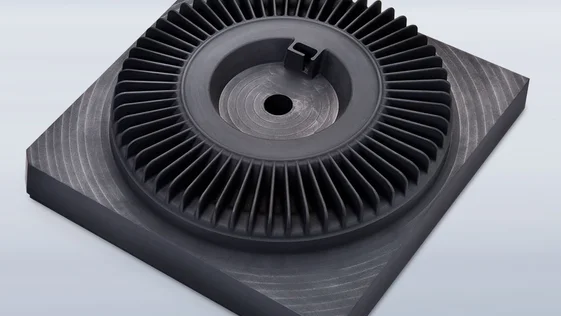

ELLOR® is a a complete range of isostatic grades, from universal to micro-grain graphite dedicated to Electrical Discharge Machining (EDM), also called Spark Machining or Die Sink EDM. ELLOR® is a global leading brand.

ELLOR® is the most comprehensive range of graphite grades for EDM on the market.

Together with the support of our application engineers, you will be able to select the right grade for your project.

-

-

Ellor® 18

Universal fine grain grade

A medium density graphite for semi-finishing ou roughing operations in the least amount of time and at minimum cost

-

Ellor® 20

Universal fine grain grade

A graphite for both roughing and finishing operations. Ideal for manufacturing plastic moulds.

-

Ellor® 25

Universal superfine grain grade

The greater density of this grade provides a better surface finish. Its mechanical properties enhance the service life of electrodes.

-

Ellor® 30

Exceptional superfine grain grades

The surface finish is better and electrode wear is always the lowest.

-

Ellor® 40

Exceptional superfine grain grades

The surface finish is better and electrode wear is always the lowest.

-

Ellor® 50

Exceptional superfine grain grades

Very fine structure and high density: very precise machining details and remarkable surface finish, whilst reducing electrode wear.

-

Ellor® DS4

The premium ultrafine grain graphite

Exceptional surface finish, outstanding strength and wear resistance.

-

-

ELLOR® isostatic graphite from Mersen has numerous advantages, making it the preferred material being used for die-sink electrodes.

- It is easy to machine.

- It is very resistant to thermal shock.

- It has a low coefficient of thermal expansion (3 times lower than copper) which guarantees stability of electrode geometry during EDM.

- It does not melt, but goes directly from the solid state to the gaseous at 3400°C, which reduces wear.

- Its density is 5 times lower than that of copper, which results in lighter electrodes.

- It provides a higher metal removal rate than copper with less wear.

- It has the unique characteristic that the wear ratio tends to decrease as the peak current increases.

-

-

Product Literature

Technical documentation

Ellor® Graphite Grades for Electrical Discharge Machining (EDM)

pdf - 4.35 MB | Nov. 28, 2024