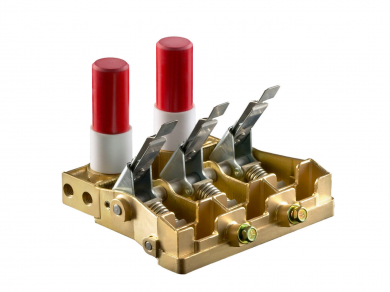

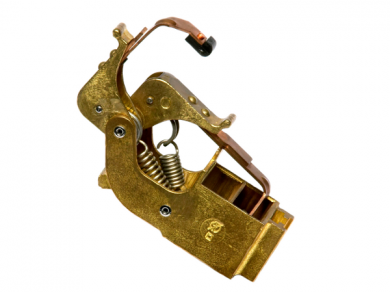

Brush-holders for DC motors

DC motors brush-holders: main characteristics

- Robust

- Molded or machined

- Selected materials (non-ferrous alloys, anti-corrosion...)

- Customized designs

- High quality solutions

- Adapted pressure systems (wound or coil springs)

- Single or multiple box

- Insulating studs

- Brush-holder attachment arm

- Fit any type of brush rocker or brush gear assembly

Carbon brushes for DC motors: applications

Brushes from Mersen lead the way in such adverse applications of DC motors as: traction (locomotives, metros, mining…), lifting (forklifts, cranes, elevators…), conveyors (mining, cement and metalworking industries), extruders (plastics, metallurgy), and also winders, ventilators, pumps, etc.

Discover our range of products for each market:

- Electric and Diesel Electric Locomotives (traction motors)

- Transit & Metro (traction motors of metros, tramways or trolleybusses)

- Aerospace (auxiliary motors)

- Metallurgy (rolling mills, winders, wire drawing machines, extruders, winding machine)

- Paper plants (paper machines, winders)

- Cement plants (furnace motors, ventilators, ground or aerial conveyors)

- Plastic Industry (extruders)

- Forklifts (lifting motors, traction motors)

- Mining (draglines, shovels, wheel motors for front loaders and trucks, conveyors)

- Ports & marine (lifting motors for cranes and gantry cranes, propulsion motors, onboard motors)

- Oil & gas (drilling, lifting, pump and anchor motors)

- Elevators (lifting, ski lift motors)

- Ski lifts (motors)

Related Products

Contact France

Sales & Engineering

F-80084 Amiens

+33 (0)3 22 54 45 00

Sales & Engineering

Annekal Taluk

560099 Bangalore, Karnataka

+91 80 68455121

+91 80 68455127

Sales & Engineering

碳刷, 刷架, 滑环组件, 工业受流 电机和发电机的电气解决方案

Sales & Engineering

5 andar- Cj. 502.

Bairro Mirandópolis

CEP: 04046-500

+55 11 2348-2360

Contact France

Sales & Engineering

F-80084 Amiens

+33 (0)3 22 54 45 00

Sales & Engineering

Annekal Taluk

560099 Bangalore, Karnataka

+91 80 68455121

+91 80 68455127

Sales & Engineering

碳刷, 刷架, 滑环组件, 工业受流 电机和发电机的电气解决方案

Sales & Engineering

5 andar- Cj. 502.

Bairro Mirandópolis

CEP: 04046-500

+55 11 2348-2360