Graphilor®:Extruded and isostatic impervious graphite

Mersen offers the widest range of impervious graphite materials on the market, whether isostatic or extruded graphite grades.

Mersen offers the widest range of impervious graphite materials on the market, whether isostatic or extruded graphite grades.

Brochures

pdf - 3.82 MB

-

Impervious graphite is widely used for chemical applications, due to its excellent thermal conductivity, corrosion resistance and mechanical strength.

Impervious graphite is a composite material made of 80 to 85% of synthetic graphite and 15 to 20% of phenolic resin depending on the selected graphite grade. It is used to manufacture corrosion-resistant process equipment such as heat exchangers, columns, or ejectors for the most corrosive applications.

Mersen offers the widest range of impervious graphite materials on the market, whether isostatic or extruded graphite grades.

-

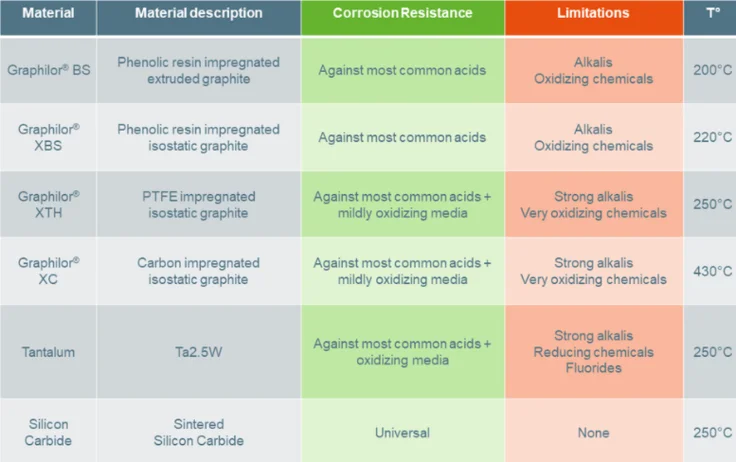

Graphilor® XBS, XC and XTH are Mersen's isostatic impregnated graphite materials.

Isostatic graphite has a very small grain size and hence very low porosity, which gives it an increased mechanical strength. Mersen produces internally its own isostatic graphite at our Saint Marys, Pennsylvania, USA and Chongqing, China plants, which guarantees full traceability and the highest quality.

Graphilor® is a unique material with phenolic resin (XBS), PTFE (XTH), or Carbon (XC) impregnation.

-

Graphilor® BS

Graphilor® BS is a phenolic resin impregnated extruded graphite.

- It contains between 18 and 25% of phenolic resin.

- It has a maximum design temperature of 200°C.

- It has an excellent corrosion resistance against common acids such as hydrochloric acid, hydrofluoric acid, hydrobromic acid and sulfuric acid.

- It has a limited resistance against bases and oxidizing media such as nitric acid, chlorine, bromine or hydrogen peroxide for example.

- Graphilor® BS is excellent corrosion resistance against common acids.

Mersen manufactures cylindrical block heat exchangers, cubic block heat exchangers, annular groove heat exchangers and shell and tube heat exchangers in Graphilor® BS.

-

Graphilor® XBS

Graphilor® XBS is a phenolic resin impregnated isostatic graphite.

- It contains much less phenolic resin that Graphilor® BS.

- It is mechanically stronger than Graphilor® BS and has a maximum design temperature of 220°C.

- It has an even better corrosion resistance than Graphilor® BS against common acids.

- It has a slightly better resistance than Graphilor® BS against bases and oxidizing.

- Graphilor® XBS is dedicated to the toughest but non-oxidizing ultra-corrosive applications.

Mersen manufactures cylindrical block heat exchangers, cubic block heat exchangers, annular groove heat exchangers and shell and tube heat exchangers in Graphilor® XBS.

-

-

Graphilor® XTH

Graphilor® XTH is a PTFE impregnated isostatic graphite.

- It contains only PTFE.

- It has a maximum design temperature of 250°C.

- It has an outstanding corrosion resistance against common acids such as hydrochloric acid, hydrofluoric acid, hydrobromic acid and sulfuric acid.

- It has an improved resistance against bases and oxidizing media.

- Graphilor® XTH is dedicated to applications with slightly oxidizing media such as nitric acid for example

Mersen manufactures both Cylindrical Block and Cubic Block heat exchangers in Graphilor® XTH

-

Graphilor® XC

Graphilor® XC is a carbon impregnated isostatic graphite.

- It has maximum design temperature of 430°C.

- It has an outstanding corrosion resistance against common acids.

- Graphilor® XC is dedicated to high temperature applications.

Mersen manufactures both Cylindrical Block and Cubic Block heat exchangers in Graphilor® XC.

-

-

Graphilor® manufacturing steps

Artificial graphite is manufactured from a mixture graphite, pitch and others. After molding and firing in an inert environment at around 1,000°C, an amorphous and hard intermediate form of carbon is obtained that does not conduct heat or electricity very well.

By heating it to around 3,000°C in the absence of any air, the carbon is purified and crystallized in a mild, greasy form conducting electricity and heat that can withstand chemical corrosion and very high temperatures. This is artificial graphite or electrographite.

Components measuring up to half a cubic meter can be produced. The first graphitization patent was filed by two engineers working for Société Le Carbone in 1893.

Then this material is impregnated with phenolic resin to make it impervious and enhance its mechanical characteristics.

Mersen produces internally its own isostatic graphite at our Saint Marys, Pennsylvania, USA and Chongqing, China plants, which guarantees full traceability and the highest quality.

-